An Illustrated History of Chester Leadworks

An Illustrated History of Chester Leadworks

Geoff Pickard

216 pages. 275x215mm. Printed on gloss art paper with colour laminated board covers.

ISBN13 : 9781911038238

£25.00

Geoff Pickard

216 pages. 275x215mm. Printed on gloss art paper with colour laminated board covers.

ISBN13 : 9781911038238

£25.00

Cornwall and Devon. These now stand as silent monuments to the mining history for which the two counties were once justly famous. This book introduces these remarkable engine houses by providing an illustrated guide to those in East Cornwall and Devon using contemporary and archival photographs supplemented with brief descriptions of the engines the buildings once contained, simple interpretations of some of their key features, and short histories of the mines of which they were part. It is not an exhaustive treatment,

An Illustrated History of Chester Leadworks - Sample Images

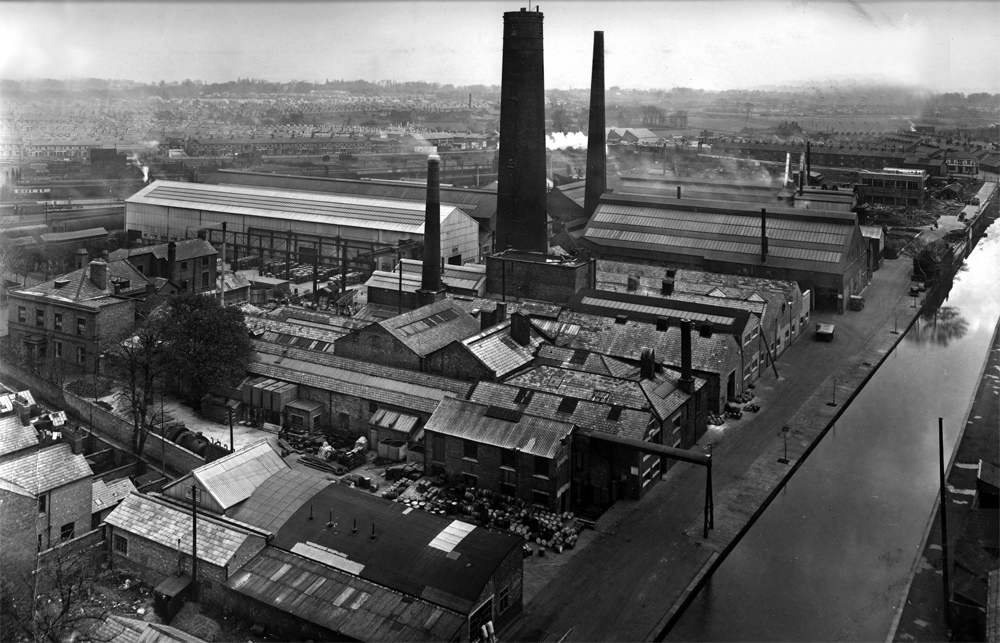

1951 saw the start of a major rebuilding programme which transformed production departments, office accommodation and general amenities across the site. The first signs of this are evident with the large white asbestos-clad warehouse to the left of the shot tower. This replaced one of the 1830 buildings which had been demolished following the end of white lead production. The steelwork frame for another similar structure is in the process of being erected immediately to the left of it. These two new buildings would eventually house the casting, fabrication and chemical plumbing departments which grew rapidly around this time and were eventually set up as a separate company in the 1960s. The Company house on the left of the photograph was also completely renovated and the collection of buildings in the foreground were demolished to make way for a new sheet mill. Grosvenor Museum, Cheshire West Museums

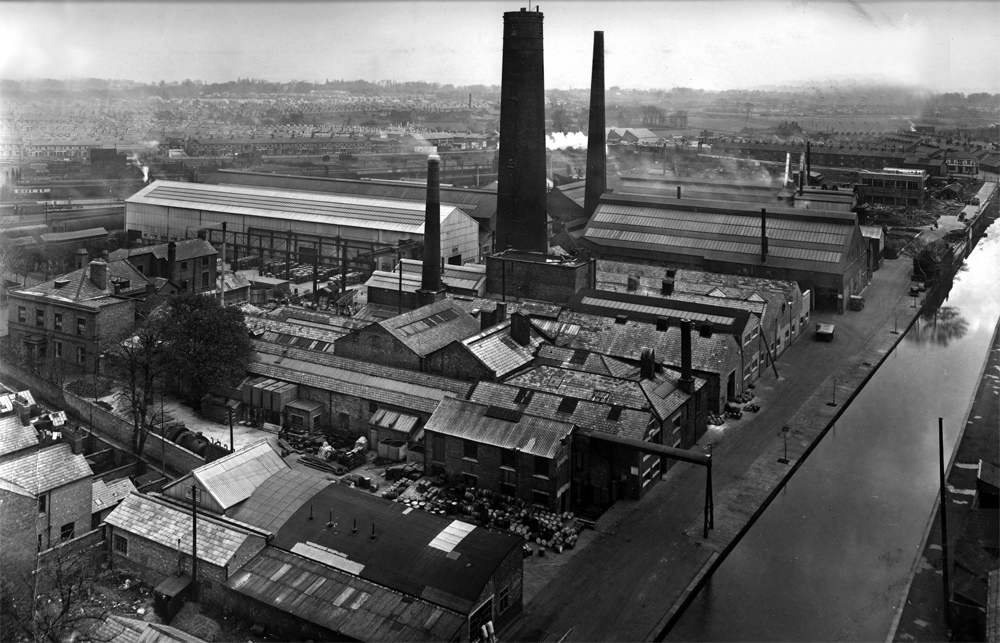

The press is in full operation and in the process of producing a coil of heavy duty pipe, probably for use in the chemical industry. The hydraulic ram can now be seen coming up out of the floor and has already pushed the container upwards by around three feet. The pipe has emerged from the top of the press and passed through a water spray to cool it prior to being coiled. This last operation could be quite difficult with this size of pipe and required two men to manually bend it round the coiling device. Pipe over three inches in diameter obviously could not be coiled in this manner and was allowed to rise vertically out of the top of the press and cut into appropriate lengths using a circular saw. Grosvenor Museum, Cheshire West Museums