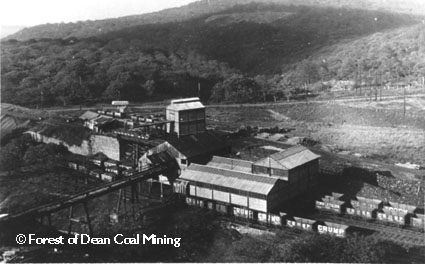

The pit-head alongside the Miery Stock to Lydbrook road.

The screens were located at Miery Stock

and connected to the pit-head by an endless rope haulage.

This can be seen on the embankment centre

left.

Although the screening plant for Arthur & Edward was situated above Miery Stock tunnel the actual shafts themselves were a little distance away. The choice of location for the screens was perhaps governed by the fact that the Lydney & Crump Meadow Collieries Co. Ltd. were originally planning to sink a new shaft at Miery Stock. An application to the Crown for permission to sink this new pit seems to have been made in 1908, as in August 1911 the colliery company were notified by the Crown that the time allowed to carry out the work would expire in 1912. In reply the colliery company asked for an extension of time until 1915 but again, nothing was done by this date. In February 1932 the sinking of the pit was once again contemplated and the company appealed for financial help in the undertaking. However, no money was forthcoming and the shaft was never sunk.

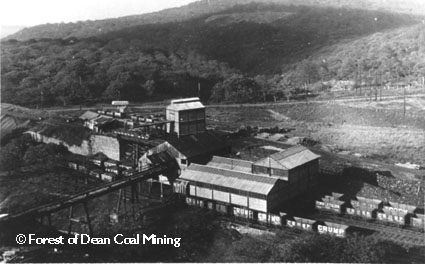

The pit head for Arthur & Edward was situated alongside the Miery Stock to Lydbrook road and was connected to the screens by an 800 yard long incline upon which was laid a trolley-way, worked by an endless rope, known locally as ¨the Creeper¨. It spanned the Miery Stock-Lydbrook road by a trestle bridge 60 feet long and 30-35 feet high and at the other end of the incline, 250 yards of trestling carried the rails over the Mitcheldean- Monmouth road and then into the screens. The trestling work was of a substantial nature and where it crossed the roads it was supported by iron pillars on concrete beds.

Of the pit itself the 1841 Coal Awards state that a Benjamin Gwilliam of Joyford, a free-miner, made an application for the Arthur & Edward gale at some time between 1832 and 1838. The application was not granted but Gwilliam, together with Thomas Butler of Edinwall, acted as though it had been and commenced work ´at a considerable expense´. In 1841 it was reported that the concern was ´extensive and in the course of opening´. Sinking of the shafts was underway, there being ´two pits and two steam engines´. This statement throws into doubt the locally held belief that the pit was sunk in, or soon after, 1815 which stems from the fact that the pit is also known as ´Waterloo´. It is far more likely that this name comes from the nearby Waterloo Mill.

At some time between 1838 and 1841 Butler, who had an 11/12ths interest in the concern, mortgaged his holding to a John Ponsford Osbourne, suggesting that the colliery may have been in some difficulties. In 1846 the output of the colliery was given as 3,259 tons and is credited to J. P. Osborne. This may have been the year in which the first coal was won as no figures are given for the preceding four years.

The next known reference to Arthur & Edward is in July 1853 and comes in the form of an advertisement in the Mining Journal. This states that the Arthur & Edward and the Miery Stock Collieries would be sold by auction on Thursday 21st July. (Miery Stock was first galed in February 1843 to William Court of Coleford and William Knight of Ruardean.) Unfortunately the advertisement does not state who the vendors were but it does say that there were two shafts sunk to the coal, a distance of 85 yards. Also there were two steam engines, one of 90 h.p. used for pumping water and one a winding engine of 14 h.p. capable of lifting 100 tons of coal per day. The underground workings were said to be formed of strong arched roads and headings and also that there was another shaft, called Bennett´s Pit, further up the hillside to the south-west which, it was stated, could be worked to yield 100 tons a day.

In December 1853 a company called the Arthur & Edward & Mirey Stock Colliery Company was formed with a capital of £25,000 in 1,000 £25 shares. The majority of the directors came from London and included Osbourne who was stated to be a merchant of Colchester. A Mr. Hiram Williams, of 61 Moorgate St., London, was appointed engineer, manager and secretary with his address being used as the registered office. The company was formaly registered on 21 March 1854. In July 1855 the annual report of the company showed that they had sold coal to the value of £24.7.5 whilst expenditure, which included a new bridge, a coke oven and a new engine, came to £9,759.7.5.. Taking advantage of the new company laws it was announced in October 1856 that they were to become a ‘limited’ company and this was finally completed on 4 January 1859. However, on the 14th of that month the company was voluntarily wound up. This was not before the company had been involved in some debate in the Forest over the transportation of their coals. The Severn & Wye classified the coal from Arthur & Edward as High Delf and as such it was priviledge to half tolls over the tramroad. This very much upset the other colliery proprietors in the district. A speech made in later years by George William Keeling, the Severn & Wye engineer touched on the matter of the rates and also gave a clue as to why the company had possibly failed in that apparently the colliery was overcome by water and was closed in 1857.

In January 1860 the colliery was up for sale by auction at the King’s Head Hotel in Gloucester. The plant was said to include three powerful steam engines in substantial stone buildings, together with boilers and all necessary gear for pumping and for lifting upwards of 100 tons of coal per day. Also included were trams, railways, weighing apparatus etc. The total area of the gale was 180 acres which contained about 1,200,000 tons of unworked coal. Underground the workings were part arched in stone and were apparently kept free of water at only half the pumping power of the engine. It is unknown if the sale was sucessful.

The Crown records show that arrears of dead rent on the Miery Stock gale stood against Osborne in 1861 to the amount of £120. A newspaper report in May 1910, relating to the purchase of Arthur & Edward by the Lydney & Crump Meadow Co., states that the last attempt to work the coal was by a Welsh company who abandoned it ‘some 50 years ago’, although this would give a date c1859 which would fit with the winding up of the Arthur & Edward & Mirey Stock Colliery Co. Ltd.. Details of the gales history now become extremely sparse, although it would appear that by April 1873 the ownership of the gales was in the hands of one Henry Hemsley Severs, who, in that month, agreed to sell the concern to the Ross and Monmouth Collieries Co. Ltd. This company was set up specifically for the purpose with a capital of £70,000 in 14,000 £5 shares. The subscribers to the company were all from London or Reading but the concern was obviously not a tempting proposition as the company appears never to have started business. It was dissolved in January 1885 after nothing was heard after 1874. In June 1877 it was stated that the time to open the Waterloo Colliery given by the Crown was about to run out and notice had been sent to the owner Mr. Barrett who possibly therefore had purchased the gales from Severs. Some Crown correspondence with the Lydbrook Deep Level Colliery Co. in August 1885 reveals that Arthur & Edward and Miery Stock had been up for auction in 1883 with no reserve. No one, however, would offer anything for them, although they had been sold for £7,000 a few years before. In February 1889 the New Bowson Colliery Co. were debating the purchase of Arthur & Edward and this was carried out during the year. In November 1894 they wished to drive as deep a pit on the Arthur & Edward gale as necessary to drain their Favourite Gale. This gale they wished to open up and work as part of the East Slad Colliery to the north of Cinderford. In May 1895 it was reported that in working the Britania Gale, again worked as part of East Slad, some of the coal in Arthur & Edward was worked. Once this trespass was pointed out the New Bowson Co. bought the gale. Behind the New Bowson Co. were the families of Holden and Illingworth.

In 1903 they had plans

drawn

up for sidings to serve the colliery but no work was done. It was Sir

Angus

Holden for the New Bowson Co. who in February 1908 assigned to the

Lydney

& Crump Meadow Co. some land at Lydbrook, probably that at Miery

Stock.

The Lydney & Crump Meadow

Collieries

Co. Ltd. was first incorporated in 1884 and worked the Bilson and Crump

Meadow collieries near Cinderford whose works were in the ‘Upper

Series’

seams and produced house and gas coals. It was because the company

could

foresee the exhaustion of these measures that they acquired the new

North-Western

United gale in 1908. This gale was one of the ‘deep’ gales formed after

the 1904 Dean Forest (Mines) Act and the area included Arthur &

Edward.

The new owners began work at Arthur & Edward immediately. Here they had an advantage over other concerns, such as the Cannop Colliery Co. who were also set up to work the deeper measures, in that they did not have to sink any shafts. They merely had to de-water those already in existance and this operation was carried out using steam pumps hung in the shafts. The water problem was also helped by Cannop who, in addition to all their own water, were also in part draining Arthur & Edward! Once pit bottom was reached the arching was found to be in as good a condition as when abandoned 50 years or more ago. However, some of the interior workings were found to have fallen in and it was necessary to drive new roadways out beyond the new workings and into the solid coal. On the surface at the pit-head it was necessary to erect new engine houses and offices, together of course with the screens at Miery Stock and ‘the Creeper’ in between.

A newspaper report in May 1910 gives details of the machinery installed at the colliery. The winding engine at No. 1 pit was built by the Sandycroft Foundry and Engineering Co. of Chester and had a pair of 18" x 3' cylinders and a 6' 6" diameter winding drum. The winder on the No. 2 shaft had two 16" x 2' 4" cylinders and an 8' diameter winding drum and was built by Pattison Bros. Ltd. of Sheffield. The main pumping engine was built by Messrs. Hawthorn & Davy.

Although the shafts were only

about

85 yards deep the Coleford High Delf seam was followed by dipples to a

depth of around 350 yards. In May 1910 about 200 men were

employed

and about 120 tons per day were being raised. In August 1911 it

was

reported that since November 1907 Arthur & Edward had been

unwatered

and it was said around this time that the colliery was producing 500

tons

per day. The area of the North Western United gale was extended

over

the years by the aquisition of other gales such as Alexandra

No. 3 in 1911, Lydbrook No. 3 in 1929 and the Serridge No. 2.

The pit-head alongside the Miery Stock to Lydbrook road.

The screens were located at Miery Stock

and connected to the pit-head by an endless rope haulage.

This can be seen on the embankment centre

left.

In 1928 the colliery was

completely

electrified with mechanical coal cutters and conveyor belts also being

installed. In March 1934 twenty men employed in the truck repair

shed at Miery Stock were given their notice as the colliery

company

had made arrangements with Wagon Repairs Ltd. to maintain the stock of

wagons. Two men were still to be employed at Waterloo whilst the

other men were to be offered alternative jobs at the colliery or at the

Wagon Repairs Ltd’s. depot at Lydney Junction. Between 1944 and

1946

virtually all of the coal face equipment was replaced. Some

output

figures for this period are given below.

| Year | Arthur & Edward | Forest of Dean | % |

| 1938 | 192,172 | 1,183,628 | 16.3 |

| 1939 | 183,576 | 1,168,013 | 15.7 |

| 1940 | 174,312 | 1,081,400 | 16.1 |

| 1941 | 153,161 | 973,903 | 15.7 |

| 1942 | 150,699 | 929,358 | 16.2 |

| 1943 | 157,151 | 882,660 | 17.8 |

| 1944 | 149,073 | 867,448 | 17.2 |

| 1945 | 142,868 | 830,023 | 17.2 |

| 1946 | 147,254 | 797,835 | 18.5 |

The colliery continued under the

management of the Lydney & Crump Meadow Collieries Co. Ltd. until

1947

and the formation of the National Coal Board. One date that will always

be remembered in the history of Arthur & Edward, and indeed in

the

Forest itself, is June 30th 1949. It was on that date at the

commencement

of the day shift that a breach was made into the old workings of the

East

Slad Colliery which were filled with water. Initially only some dirt

and

shale were coming from the roof accompanied by rumbling sounds. The

order

was soon given to the men to get out and about half a minute later the

water broke in. The men managed to get back to the bottom of the shaft

where a line of full carts had been pushed right to the edge. These

allowed

the men to get into the cage, even when the height of the water was

above

that of a man, the last arrivals in fact had to duck under the water

surface

in order to clear the roof beams. The signal key for the cage was soon

submerged and in order to communicate with the winding engineman the

emergency

signal system had to be used which involved a man riding up and down

the

shaft on the top of the cage. The man who carried out this dangerous

task

was Harry Toomer and for which he was awarded the British Empire Medal.

By this method 177 men were got

to safety by 11.00 am. However, five men were still missing and one

more

descent in the cage was made in the hope of finding them but by this

time

the workings were full of water. Thankfully the five men were safe and

somehow managed to link up. They found that the telephone to the

pit-head

was still working and soon those on the surface knew the men were

alright.

The five were told to head for the old Pluds Colliery shaft which,

luckily,

had been re-opened a few months previously as extra ventilation for

Arthur

& Edward.

Here a temporary sheerlegs and a

winch were quickly erected and two volunteers were lowered down the 130

yard shaft. At 3.15 in the afternoon the two met the trapped men and

all

were safely winched to the surface by hand.

Rescuers working at the top of the Pluds shaft following the flooding on the 30th June 1949.

Work soon commenced on recovering the colliery, pumping operations lowered the water level sufficiently to get through ventilation within a couple of days and after two weeks the men were back at work having been found temporary work at other pits in the meantime.

At its peak the colliery had an output of 4,000 tons per week. The closure of the pit was originally planned for February 1960 but in the event the last day of operation was December 23rd 1959. The workforce was found alternative employment at the Princess Royal and Northern United Collieries.

see also:-

Dean Forest Mercury

27 May 1910 ‘Colliery Development in Dean Forest’.

COAL38 465

Messrs. Truck Repairs, Birmingham

have use of a portion of the Truck Repair Shop, rental £25. 14. 0.

Norton Harty 4-belt screening

plant

15 H.P. Pickrose haulage (7 Rise)

15

“

“

“

(Coffin Jinney)

5

“

“

“

(80 Dipple)

5

“

“

“

(93 Dipple)

15 H.P. Becander haulage (Stroke)

15

“

“

“

(2 Face)

Horses 11

Pit tubs 648

Main line wagons 12

tons

60

10

tons 414 + 29 (443)

8

tons 3 + 1 (4)

Balance wagon bogie (internal

user)

1

20T Pooley land sales weighing

machine

30T

“ tare weighing machine

60T

“ truck weighing machine

COAL36 48

1 February 1912 North Western

United Gale comprised of Arthur & Edward in the Coleford High Delf,

Miery Stock, Serridge, Favourite and Alexandra gales in the Coleford

High

Delf, Whittington, Brazilly and No Coal veins and Old Engine No.2 gale.

Agreement with Wagon Repairs Ltd.

1/3/34 - 28/2/39. Annual payment of £5 8s. 6d. per wagon

per

annum. Rebuilt wagon No. 740.

Coal 34 504

1946 output 147,000 tons.

Colliery totally electrified in

1928 and in thet year coal cutters and conveyors were first installed.

During 1944-46 nearly all coal face

equipment was replaced.